Company

FDU Smart Highspeed Injection for Sustainability

Our environment is important to us. We are fully aware of the responsibility that we have as a supplier for the plastics industry. For this reason, we, FDU Hotrunner GMBH with our parent company HAILDMAIR, have been focusing on sustainable corporate management for years and have optimized the operating infrastructure and production in the direction of sustainability.

With the FDU technology, we also offer our customers the opportunity to make their production more efficient and sustainable. The use of the FDU wide slot nozzle saves energy costs by reducing the cycle time and lowering the melt temperature, promotes the use of recycling materials through the use of the latest hot runner technology and thus helps you to save CO2.

With the FDU wide slot nozzle, the specific injection pressure can also be reduced, whereby the clamping force is reduced and thus smaller machines with less CO2 emissions can be used.

You can find more information about the sustainability strategy of our parent company HAIDLMAIR here.

Example

Example white goods BSH base carrier

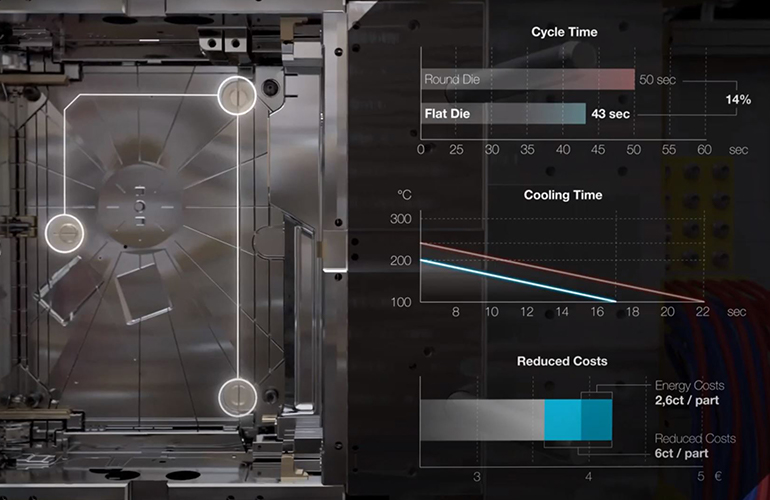

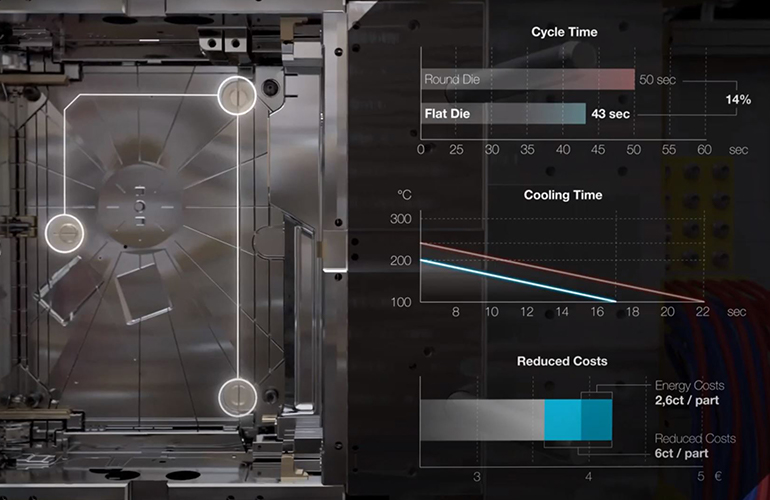

Considerable energy savings through the use of FDU in production at BSH at 3.6 million units per year (all values measured in series production at BSH)

- Cycle time reduction 14%

- lower pressure loss

- Closing force reduction from 10,000kN to 8,000kN

- higher flow paths

- Reduction of component weight possible

- Use of recycled material

- Saving energy costs per piece 2.6c

Co2 reduction by saving electricity within EU: 300 to / a

Contact

ACHIEVE GREAT THINGS TOGETHER

Get in touch with us. We will be happy to present the advantages of our patented, innovative hot runner solution for your higher productivity in a personal meeting. We look forward to meeting you!

Contact usWe will process your request as soon as possible and get in contact with you!